Glass has always been present in furniture construction. However, a fascinating way to combine glass with wood, shown in the projects presented here, is a real masterpiece – in addition to my own idea and workmanship.

Glass has always been present in furniture construction. However, a fascinating way to combine glass with wood, shown in the projects presented here, is a real masterpiece – in addition to my own idea and workmanship.

Glass is an unusual material – above all, exceptionally beautiful. The glass plates are transparent and have an impression, as if they weigh nothing at all. Their edges cause a break, light reflection and scattering. Due to its aesthetic value, glass has always been used as an element of furniture.

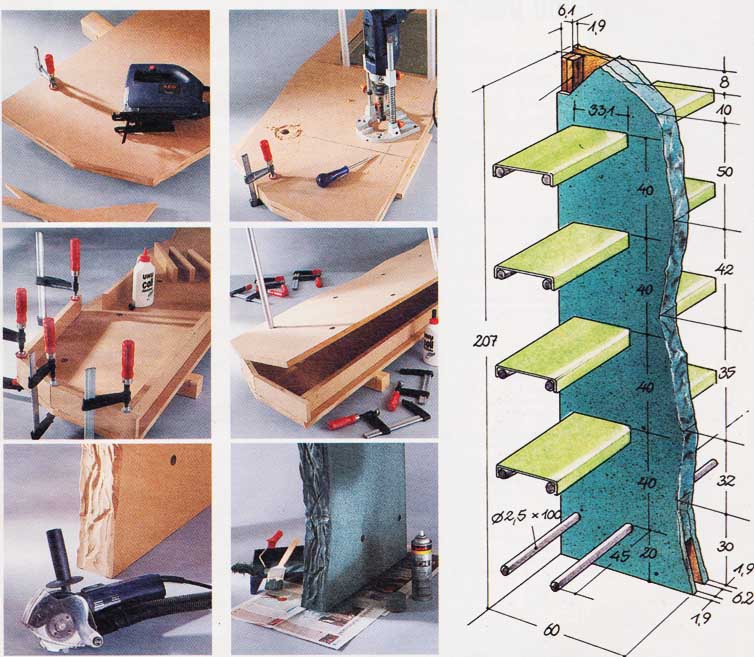

In our projects, we tried to bring out and emphasize all the advantages of glass. The glass plates used in them act as shelves. In addition to the function of the load-bearing elements, they are also extremely elegant decorative elements – in the first project it is structured industrial glass, with a U-shaped profile, in the second proposal, transparent glass with a thickness 8 mm, with ground edges. The sophisticated taste of the presented solutions is based on the combination of materials – the combination of wood and glass makes, that the shelves look exceptionally noble and modern. With its advantages, it is furniture, which cannot be bought anywhere, only for DIY enthusiasts, for self-performance.

The glass plates can simply be ordered from the glazier, where they will be trimmed according to the given dimensions, and ground on request.

The main thing is to fasten them. In the first project, aluminum pipes play the role of load-bearing elements, also being an additional, decorative detail of a piece of furniture. In the second proposal, the supporting elements of the boards are hidden behind a plywood cover. Their suspension could not be designed in a more sophisticated way!

Always drilling with a washer.

When drilling a wooden board, the underside of the board can often crack. MDF boards are particularly at risk, although this also applies to all other wood-based materials. This can be avoided in a simple way, placing a piece of board under the material at the drilling site. Thanks to this, the drill tip will not go into the empty space at the end of drilling.

Thanks to the universal milling machine and varnish, the MDF board resembles a stone surface. The shelves of U-shaped glass profiles will be quite simply placed on the aluminum tubes. The column of the rack has been arranged in an interesting way. Its appearance, similar to the irregular surface of a stone, was obtained with the Fleckstone spray varnish. It can be a gray or colored mottled surface, not perfectly smooth, but slightly rough. The form of the rack column is made of thick MDF board 19 mm. The front and top edges of the side walls of this column were cut out in the form of an irregular line. Then, intermediate elements were glued between them, and then they were further processed with a universal milling machine – until the moment, when they started to look like a broken edge of stone.

We roughly cut out the contour of the side walls of the column with a jigsaw. We process the assembled plates fastened with clamps at the same time.

We drill holes for fastening pipes with a sednik drill 25 mm. A drill stand allows for perpendicular edges. Draw the shape of the intermediate elements on the board, we cut them at the right angles and glue them. When gluing the second side wall, we use aluminum pipes as guides. The holes of both plates will lie exactly above each other. We make the imitation of a stone breaking edge with a universal milling machine. The maximum milling depth is limited to 15 mm. After priming (with green paint) we cover the edges of the column with a glossy one, clear varnish, walls with special varnish.

The rack can be positioned thanks to the wide strips of boards attached to the wall with dowels 6,1 cm. Secure the embedded column with screws, through its side walls.